The Beginning

It was in 1943 that Parliament passed an act that recognised that many miners were been struck down with what the miners called "The Dust" (pneumoconiosis’s). The Government decided to encourage employers to give ex-miners employment. Leonard Lords had taken this to heart and decided that those (in this case South Wales miners) who had been cut down by this respiratory condition could still earn a wage. It was stated that in 1945 there were over 5,000 miners suffering from this disease. The plan was that they would build a Toy Pedal Car based on the current models. To keep the cost down, it would use metal off-cuts.

It was Leonard Lord, Chairman of the Austin Motor

Co who in April

1946 summoned Rod Phillips who was an Artist attached with the Post

War Planning whose brief was to look into the future of how the

factory would look in the Post War period. He was joined by Jim

Blaikie who had join him after serving in the war, (it was a

government directive that any person who was employed before the

war, his employer would have to offer them their old job back on

returning to civilian life.

Both Rod and Jim had no experience of body design and the tooling

needed. This is where a third member Alf Ash joined the team who

had the expertise.

The team were given a disused workshop in South Works in which to

set up a design office and experimental build. So it was down to

looking at the specification.

a) Suitable for children in

the age range four to nine.

b) Most be able to have room in the front for a smaller brother or

sister.

c) Bonnet and boot to open.

d) Lights that work along with a dummy engine

Austin Pedal Cars

Austin Pedal Cars

The Austin J40 and the Austin Pathfinder is one of the most collectible pedal cars found in Australia(and one of the more expensive types) The information and pictures were obtained from the Austin Memories web site, the site that is all about Austin & Longbridge..)

(Please note The pictures are the copyright of the British Motor Industry Heritage Trust and the information given in the article was obtained from David Whyley.)

Production Stage

Although the

original idea was to use up scrap sheet metal from

Longbridge, this was only possible for small parts, the larger

panels would be produced from fresh steel strip. The Government

were willing to pay for a new factory, so it was decided to build

the factory at Bargoed in Wales. To set the factory up second hand

presses a total of nine were send down from Longbridge. The Body

Sides needed a larger capacity press and so these panels were

pressed in West Works Longbridge

Although the

original idea was to use up scrap sheet metal from

Longbridge, this was only possible for small parts, the larger

panels would be produced from fresh steel strip. The Government

were willing to pay for a new factory, so it was decided to build

the factory at Bargoed in Wales. To set the factory up second hand

presses a total of nine were send down from Longbridge. The Body

Sides needed a larger capacity press and so these panels were

pressed in West Works Longbridge

The factory in Bargoed was starting to take shape, and covered an area of 24,500 sq ft. This included a production area along with stores, offices and canteen. An up to date medical centre was essential for the work force who would be employed, and staffed with nurse and a part time Doctor. Twice a year the hospital in Cardiff would send a team along with a mobile X-Ray machine, to check on the workforce.

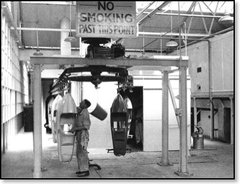

Although the Government funded the factory, Austin still had to pay rates, but this was reduced to 50% because only disabled staff were been employed on the production side. It was decided to get the plant up and running by Christmas 1948, in fact things were slipping badly and the factory was not finished till January 1949. With a manager installed and various staff from Longbridge arriving to install the necessary equipment. One interesting piece of new equipment was a process supplied by Carrier Engineering for the preparation prior to painting of the bodies. The process was called the Rotodip which the company were hoping to get Austin to installed at Longbridge. The process involves putting the welded body on to a shaft that rotates as it goes through baths of metal preparation chemicals. The management at Longbridge must have been impressed as the process was later installed in West Works.

It was

decided in the early

stages to make the Pathfinder version first, the main reason for

this is that the main body was only two pressings, and these were

been made at Longbridge. With less parts than the saloon version it

was easier to bring it out first. The first public advert for the

cars was by Selfridges in June 1949 although the company had

contacted their dealers in mid May stating that “Delivery of

Pathfinders will commence almost immediately, and the ‘Joy Roaster’

will be in production in about three months time.” Supplies were

slowly been built up, ready for the official opening of the Factory

in July 1949. The press were quite intrigued by the cars and gave

the company much valuable publicity, although I don’t think there

were any free samples given away. It appears that the Pathfinder

was joined by the Roaster at the end of 1949, which was just right

for the Christmas period. The cost of the Pathfinder was £25. 4s

with the Roaster at £20. Production figures for the two models is

unknown, as no figures were kept before 1955.

In the early years the workforce was around the 110 mark, but in

1953 suddenly increased to just under 150. From then on it rose

nearly every year until it reached a peak in 1965 employing 514.

The reason for this increase was that over the years the factory

had the presses and welding equipment to produce other small

components needed by other factories in the BMC empire. Parts such

as rocker covers, timing covers and number plates were the main

items,

Assemble Process

As stated earlier, the

Pathfinder were the first to go into production. The main

components were the body, trim, front and rear axles, pedal

assembles and wheels and tyres.

With the Pathfinder it only had two main pressings which were

supplied from Longbridge. The pressings were spot welded together

along with the facia and seat panels. As you can see from the

picture below, after having a pre-treatment via the Rotodip and

primer it passes to the paint spray booth. It would be hand sprayed

and as can be seen in the picture the bonnet travels separately.

They were available in Cream with Red Trim and also Wheels and

Grille, the other option was Red body with Beige/Tan Trim and

Silver/White wheels and grille.

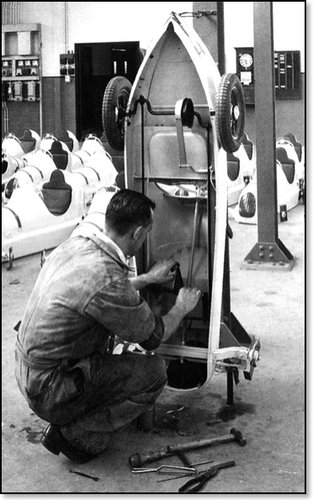

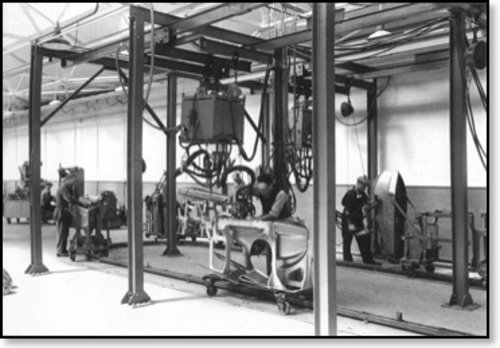

This shows assemble of the various items, including the parking brake which when operated pulls a band round a drum on the rear axle. The body is supported by a jig.

Welding line

Assemble of the saloon on jigs which can be turned over to work on the underside

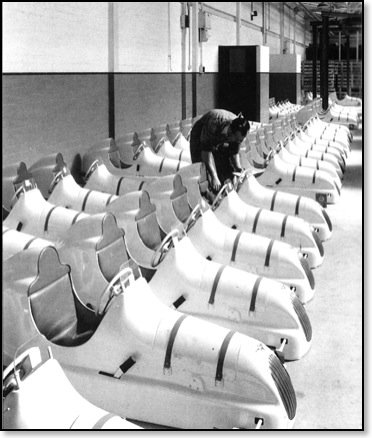

Pathfinders Waiting for Wheels

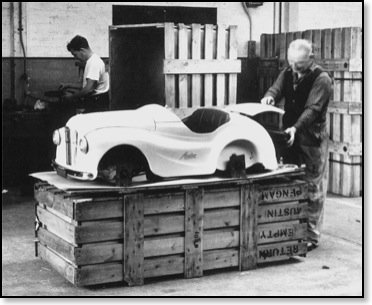

Ready To Ship

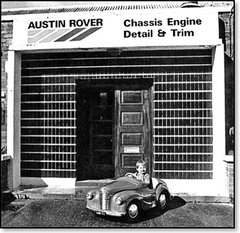

The End Of The Line

In 1971 it was

decided

to close down the factory because the glue that was used was effecting the

health of the workers.

On the 15th September 1971 the last of

the Joy Car were made all of them going to UK customers. At this

point the production total from 1955 to 1971 was 32,098, it is

believed that the figure from 1949 to 1955 was about 1,500 Joy

Roaster and over 3,100 Pathfinders.

Through The Years

The J40 was put to a multitude of uses both whilst still in production and long after.

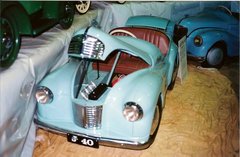

Special J40 present to Prince Charles (1952)

Note the various extras : windscreen, wing mirrors, number plate, side lights & spot light.

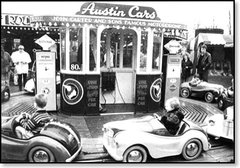

Juvenile driver training throughout the world used the J40 as their main tool.

The Austin Pedal Car Club includes an interview wit Alfred Ash.

Joy Rides

Pedalmania Images